We specialize in custom machining for parts ranging from .010” to 18” in diameter, with expertise in:

SERVICES

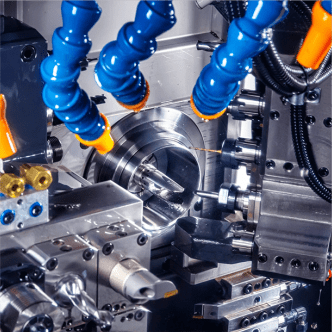

STATE-OF-THE-ART SWISS TURNING

Our cutting-edge Swiss-style CNC lathe is a one-and-done machine, ideal for high-quantity, high-quality, high-precision parts. With its high-speed production rate, this machine allows us to cut down on lead times, delivering parts faster than ever. The Swiss lathe is built for complex parts requiring precise, multi-angled cuts.

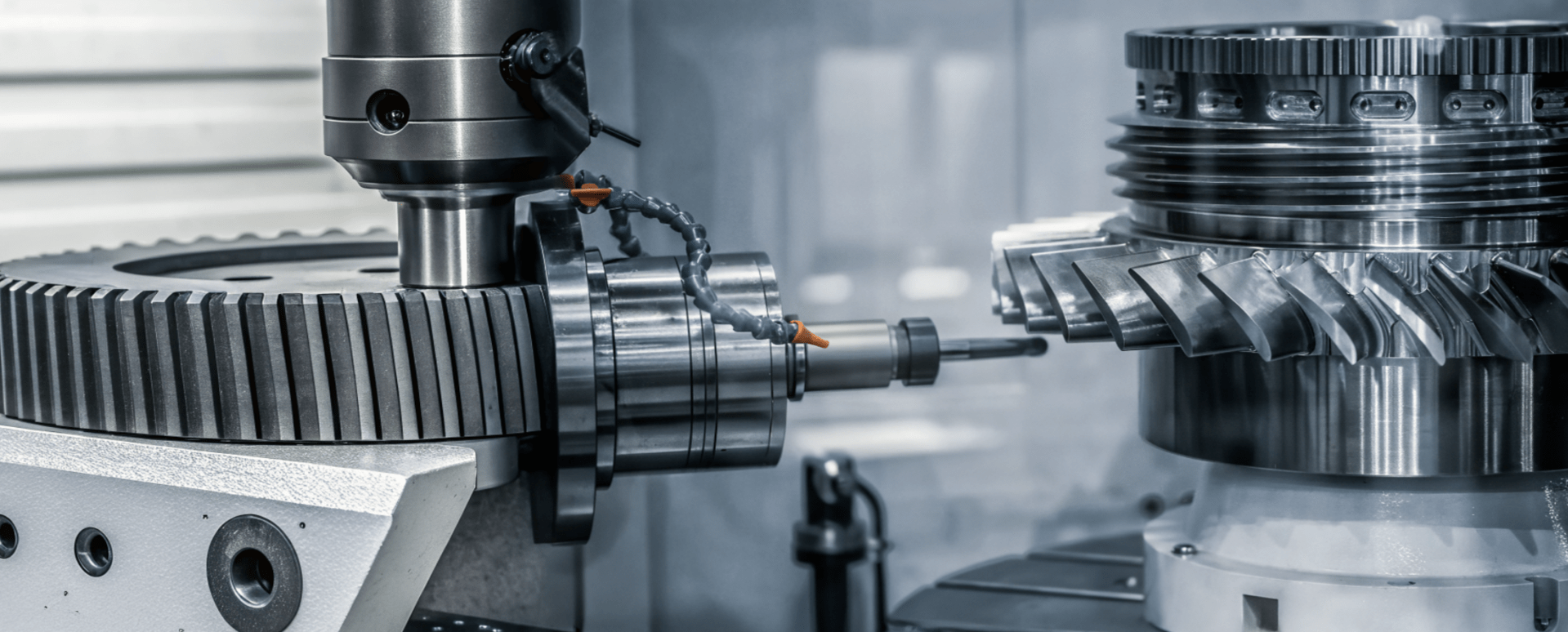

MILLING

P&N specializes in precision milling, using advanced CNC technology to create intricate components with tight tolerances. Whether working with complex geometries or high-precision parts, our milling capabilities ensure consistent quality for industries like medical, aerospace, and energy.

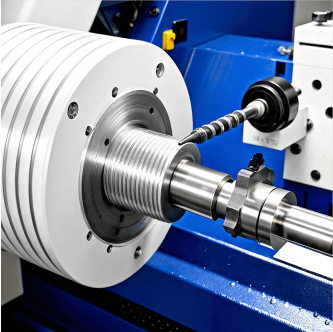

TURNING

Our turning services handle small to medium-sized parts, focusing on producing precise cylindrical components. With a range of materials, including exotic metals, we deliver parts with exceptional accuracy and surface finish.

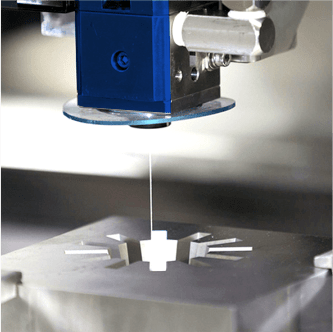

EDM (WIRE AND PLUNGE)

Using both wire and plunge EDM, P&N can machine complex shapes and tight internal features that conventional methods cannot. This capability is ideal for intricate medical components and high-precision parts.

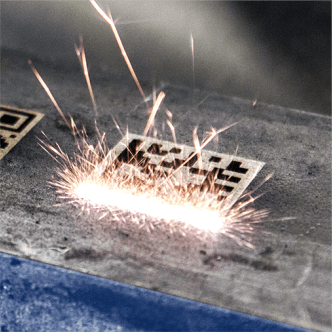

LASER ENGRAVING

P&N offers laser engraving for part identification, ensuring permanent, legible marks without compromising material integrity. This is critical for industries like medical and aerospace that require traceability.

ASSEMBLY

Our full turnkey service includes assembly, coatings, and welding, ensuring seamless production from start to finish. We leverage our extensive vendor and supply chain network to ensure that your parts are fully completed and ready for sale or use. Whether it’s specialized coatings or complex welds, we handle it all to meet your part specifications.

PROTOTYPE CONSULTATIONS

P&N provides prototype consultation services, working closely with you to refine your designs for manufacturability. We will collaborate through each process, to ensure cost-effective production while maintaining tight tolerances and high-quality results.

TURNKEY SERVICES

P&N offers full-service production, from machining to coatings and welding, tailored for precision components; From Prototypes to Production Parts

INDUSTRIES WE SERVE

P&N is FDA registered, ITAR compliant, and ISO certified. Whether your project requires high or low volumes, we are equipped to handle your needs. We provide precision components for a diverse range of industries, including:

FAQs

We manufacture custom-machined components using both conventional and CNC equipment.

The management and staff of P&N Machine Co., Inc. are committed to supplying products that meet or exceed all customers’ specifications, including price and delivery.

We are committed to the development and implementation of the company’s quality management system, complying with requirements, and continually improving its effectiveness.

P&N Machine’s quality management system has been developed to conform to the requirements of ISO 9001:2015 and ISO 13485:2016. Detailed procedures and processes have been developed for internal purposes to ensure that the company’s quality policies are implemented and effectively meet stated quality objectives and customer requirements and expectations.

Machine parts as small as .010” in diameter and as large as 18” in diameter. We can manufacture orders for a single prototype or thousands of pieces. We are a turnkey machine shop providing welding, assembly, and other services.

While we don’t currently offer these services in-house, we partner with reputable plastics manufacturers to ensure your 3D printing or injection molding needs are met.

We take pride in delivering precision parts on time, every time. By continually investing in advanced technology, we’re able to reduce lead times and improve efficiency. Just let us know your deadline — we’ll work hard to meet it.

We have the capabilities to work with all types of materials, including plastics, brass, aluminum, all types of stainless steel, tool steel, titanium, MP35N, Inconel 718, BeCu, etc.

We don’t have our own line of products. We build custom parts based on drawings or samples supplied by our customers.

Get in touch through our website or email us at sales@pandnmachine.com and attach relevant drawings or part specifications. Please be sure to include the quantity desired, the necessary lead time, any relevant notes, and your contact information.

62 Employees on a 10.25 acre site with two air-conditioned buildings totaling 70,000 square feet, controlled inspection environment of 3000 square feet

We have been in business since 1973, and we have been at our current location since 1978. We have 50+ years of precision machining experience and over 25 years of medical manufacturing experience.

Get in touch through our website or email us at sales@pandnmachine.com.

We can also be reached by phone at 281-469-9140 or by fax at 281-469-6100.

Our Hours of Operation are: Mon-Fri 8:00am-4:30pm CST

HAVE MORE QUESTIONS?

REQUEST A FREE QUOTE TODAY

From prototype consulting and manufacturing to large production runs, P&N is your go-to machine shop for tight-tolerance work. We are more than just suppliers; we are your true partners in success. Contact us today for a quote or to have your questions answered by one of our experienced professionals.